There are many types of Hydraulic Hoses, and the structure of each type is different. The performance produced by different structures is also different, and the fields of application for different performances are also different.

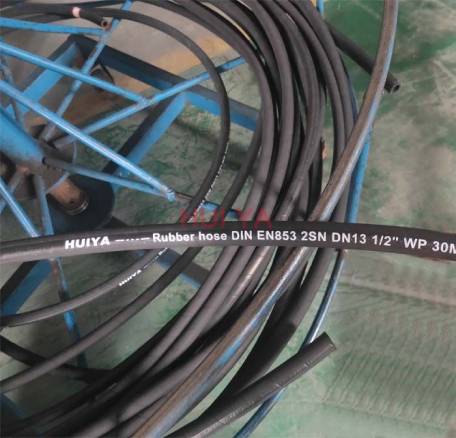

Hydraulic hoses are divided into two categories: rubber material and rubber-plastic material. According to the production process, it is divided into steel wire braided hose, steel wire wound hose, Wire Braided Hose and cloth hose

It is mainly composed of a liquid-resistant synthetic rubber inner rubber layer, a middle rubber layer, a multi-layer reinforcement layer, and a weather-resistant synthetic rubber outer rubber layer.

The inner rubber layer has the function of making the conveying medium bear pressure and protecting the steel wire or thread fiber from corrosion. The outer rubber layer protects the reinforcement layer from damage. The reinforcement layer is a skeleton material, which is used to ensure the pressure of the hose.

Hydraulic Hoses

Mainly used for mine hydraulic supports, oilfield development, suitable for engineering construction, lifting and transportation, metallurgical forging, mining equipment, ships, injection molding machinery, agricultural machinery, various machine tools, and various industrial departments mechanized and automated hydraulic systems with certain pressure. And temperature petroleum-based (such as mineral oil, soluble oil, hydraulic oil, fuel, lubricating oil) and water-based liquid (such as emulsion, oil-water emulsion, water) and other liquid transmission. Hydraulic hose made of rubber and plastic materials, also called Rubber Hose, is a new type of hose with obvious corrosion resistance and energy saving effects.

1. The hose and hose assembly can only be used to transport the designed material, otherwise it will reduce the service life or fail.

2. Use the length of the hose correctly. The length of the hose changes under high pressure and the length changes caused by mechanical movement.

3. The hose and hose assembly should not be used under pressure exceeding the design working pressure.

4. Under normal conditions, the temperature of the medium conveyed by the hose and hose assembly should not exceed -40℃-+120℃, otherwise the service life will be reduced.

5. The hose and hose assembly should not be used under the minimum bending radius of the hose, avoid bending or bending near the pipe joint, otherwise it will hinder the hydraulic transmission and conveying materials or damage the hose assembly.

6. The hose and hose assembly should not be used in a twisted state.

7. The hose and hose assembly should be handled carefully, and should not be dragged on sharp and rough surfaces, and should not be bent or flattened.

8. The hose and hose assembly should be kept clean, and the inside should be flushed (especially the acid pipe, spray pipe, mortar pipe). Prevent foreign objects from entering the lumen, obstructing fluid delivery and damaging equipment.

9. The hose and hose assembly beyond the service period or storage period must be tested and identified before they can be used.

Copyright © Hengshui Huiya New-Mat Technology Co., Ltd. All Rights Reserved Sitemap